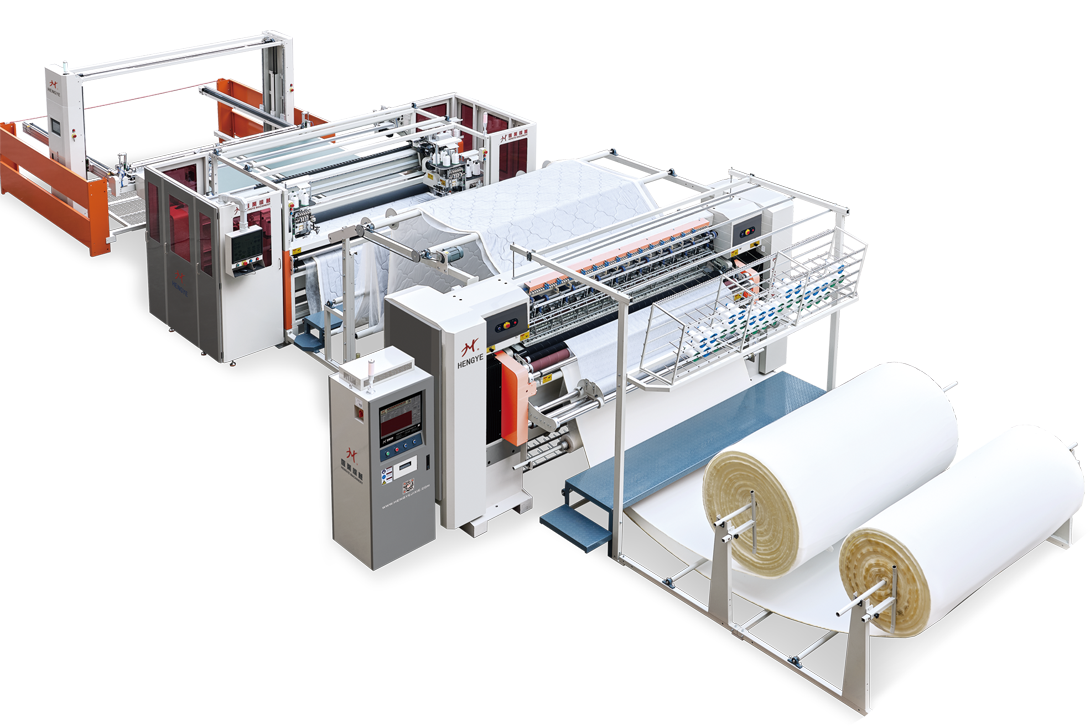

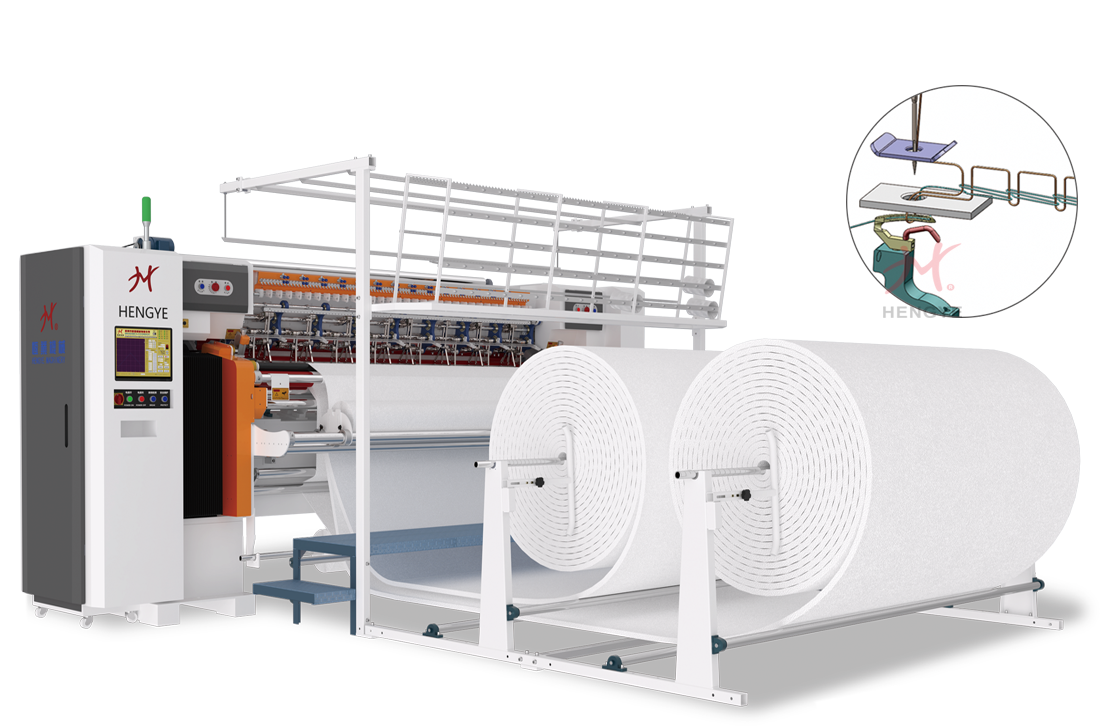

Computerized Chain Stitch Multi-needle Quilting Machine

HY-W-SJS-3

HY-W-SJS-3(Y)

Computerized Chain Stitch Multi-needle Quilting Machine

[ CE-Certification | widening | high efficiency ]

NO.1

Purpose: It is widely used for quilting high-quality mattresses, quilt covers, and household ornaments. Different patterns are available.

1гАСServo system is used in X-Y-Z axis, that can improve 30% production for independent patterns;

2гАСNewly reinforced structure makes it work more stably;

3гАСRaising supporting board makes it more convenient to operate and maintain;

4гАСY axis reduction gearbox makes it work more fluently with low-noise;

5гАСNew type retainer frame structure,with the advantages of low noise;

6гАСOptimized the mechanical structure make the higher speed and more production;

7гАСPress plate lifting can be adjusted by one-button according to different material thickness;

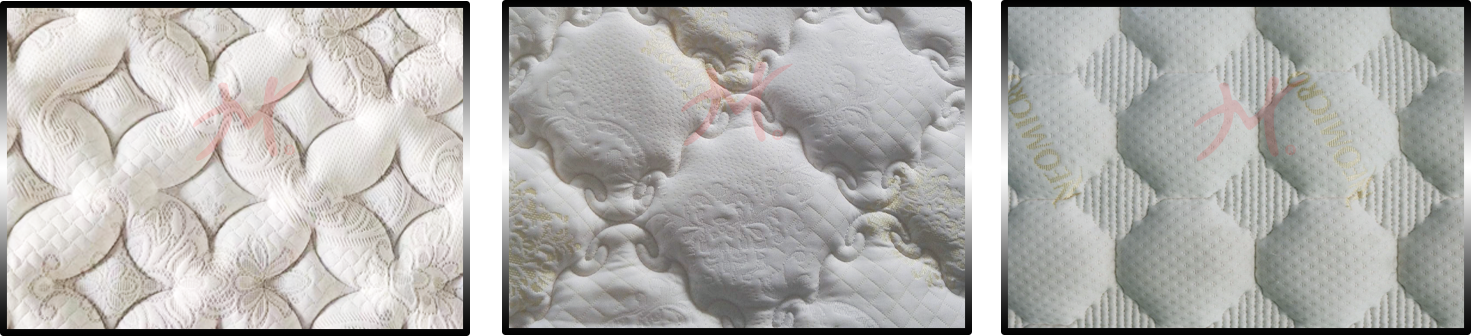

8гАСMore tight thread stitches make the quilting pattern with stronger third dimension;

9гАСNeedle bar and press plate are controlled by a doubles-winging device without cam avoiding lubrication and dirtying of material;

10гАСMulti-span and independent patterns(360¬∞гАБ180¬∞ patterns are available);

11гАСAutomatic stop motion control in case the top thread or the bottom thread breaks, automatic needle-lifting and CNC speed adjustment;

12гАСCE certificate;

13гАСOutstanding features such as high rigidity,high running speed,low vibration and noise.

14гАСNew generation of CNC system,high precision quilting,dispense with too much parameter adjustment or pattern modification during quilting;

15гАСEasy preparation of CAD drawings extremely precise;

16гАСStrong functions of pattern-combining and multi-span quilting to enable you to quilt different patterns in each row in the mattresses of different sizes;

17гАСFault detection function for ease of determining the running state of the machine at any given time;

NO.2

| Parameter(еНХдљН/Unit mm) | HY-W-SJS-3 | HY-W-SJS-3( Y ) |

| Host electrical box | Independent electric box | Integrated electric box |

| Dimension(LWH) | 4800√Ч1500√Ч2100 | 4700√Ч1500√Ч2100 |

| Quilting width | 2550 | 2550 |

| Space between needle rows | 50.8,76.2,127 [5"] 76.2,76.2,152.4 [ 6" ] | 50.8,76.2,127 [5"] 76.2,76.2,152.4 [ 6" ] |

| Space between needles | 25.4 | 25.4 |

| X-axis movement displacement | 350 | 350 |

| Thickness of quilting | вЙ§ 80 | вЙ§ 80 |

| Stitch length | 3~8 | 3~8 |

| Speed of operation | 60~300[m /hour] | 60~300[m /hour] |

| Model of needle | 24/180пЉМ23/160 22/140пЉМ21/130 | 24/180пЉМ23/160 22/140пЉМ21/130 |

| Quilting speed | 600~1200 [rpm] | 600~1200 [rpm] |

| Total power required | 8.5 KW | 8.5 KW |

| Voltage | 380V/50HZ 220V/60HZ | 380V/50HZ 220V/60HZ |

| Gross weight | 5600KG | 5600KG |

дЇІеУБдЄїжЬЇ

Leading Brand

HY-W-SJS-3 / 3(Y)

Optional: Independent electric box / integrated electric box

Appearance 1: HY-W-SJS-3 Independent electric box

Appearance 2: HY-W-SJS-3пЉИY) Integrated electric box

NO.4

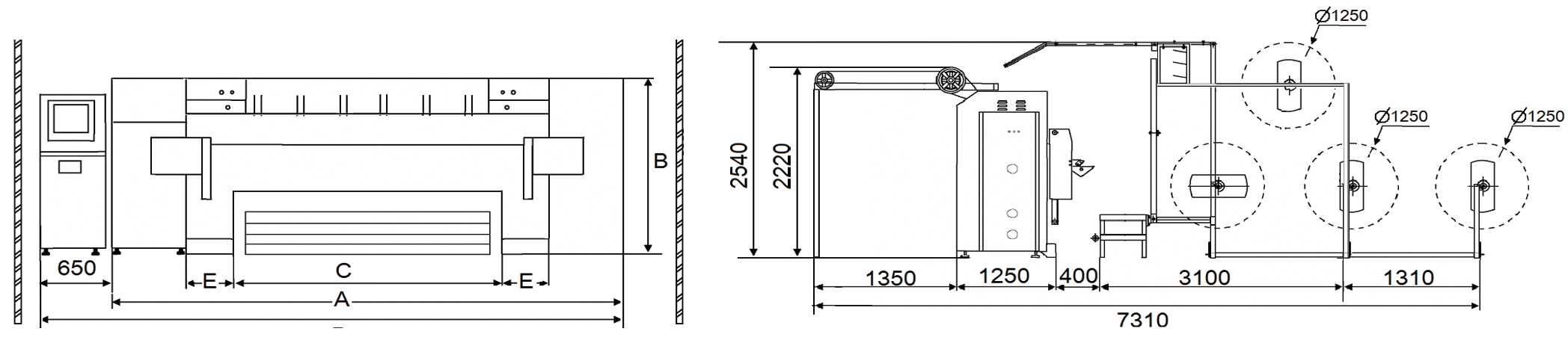

Model | HY-W-DGN | HY-W-SJS-3 | HY-W-SJS | HY-W-SJ | HY-W-BSJ | HY-W-JH |

A | 4990 | 4800 | 4700 | 4795 | 4795 | 4840 |

| B | 2120 | 2100 | 2100 | 2050 | 2050 | 2000 |

| C | 2870 | 2820 | 2820 | 2800 | 2800 | 2940 |

| D | 5690 | 5400 | 5400 | 5460 | 5460 | 5540 |

| E | 500 | 670 | 500 | 500 | 500 | 350 |

жЬЇжҐ∞зїЖиКВ

Details

зїЧзЉЭжХИжЮЬ

Quilted Effect

HY-W-SJS-3 / 3(Y)

зїДеРИжЦєж°И

Combination scheme

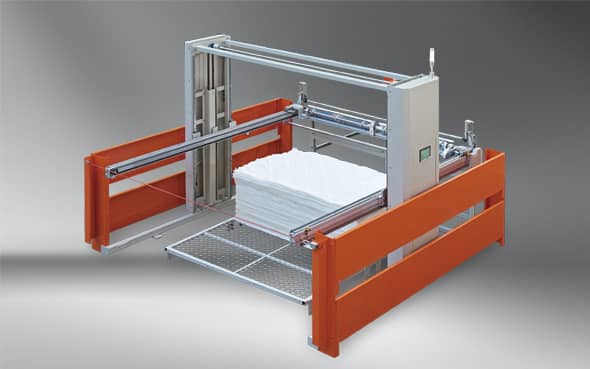

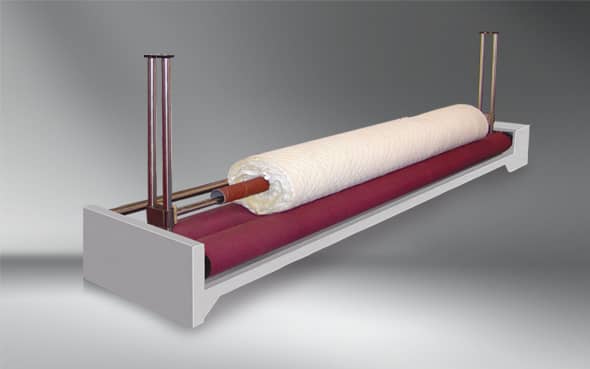

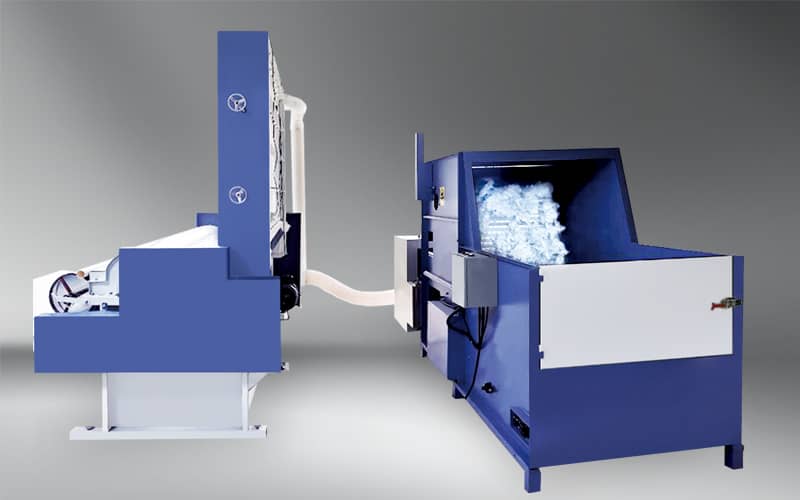

Quilting Machine | Hemming Machine | Cutter Machine | Stacking Machine | Roller DeviceпЉМWe can provide a full perfect combination according to customerвАЩs requirement пЉБ

HY-W-SJS-3 Quilting Machine

HY-FQ-2 Four Side Hemming and Cutting Machine

HY-D-1 Stacking Machine